Phát hiện lỗi và sửa chữa máy nén khí Kobelco dòng AG và SG

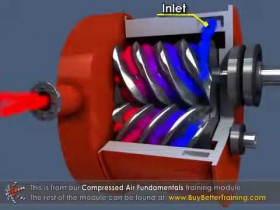

Máy nén khí trục vít có dầu Kobelco dòng AG và SG là hai dòng phổ biến nhất của hãng sản xuất Kobelco (Nhật Bản). Cùng Minh Phú điểm qua một vài lỗi thường gặp của hai dòng máy này

Lọc dầu Sakura C6205

Giá bán: Liên hệ

Lọc dầu máy nén khí Atlas Copco GA 75+

Giá bán: Liên hệ

Lọc gió máy nén khí Atlas Copco GA 75+

Giá bán: Liên hệ

Lọc gió máy nén khí Atlas Copco GA 11

Giá bán: Liên hệ

Lọc gió máy nén khí Fusheng SA 75

Giá bán: Liên hệ

Lọc dầu máy nén khí Fusheng 55kw

Giá bán: Liên hệ

Lọc gió máy nén khí Fusheng 55kw

Giá bán: Liên hệ

Tách dầu máy nén khí Fusheng 55 kw

Giá bán: Liên hệ

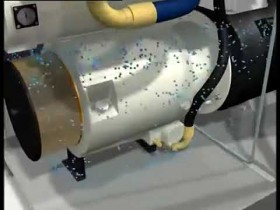

Bộ tách nước khí nén SAMG 250

Giá bán: Liên hệ

Khớp nối mềm máy nén khí -Compressor Coupling

Giá bán: Liên hệ

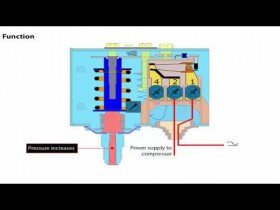

Công tắc áp lực ( Pressure switch) máy nén khí...

Giá bán: Liên hệ

Hạt hút ẩm dùng cho máy sấy khí hấp thụ

Giá bán: Liên hệ

Máy nén khí Piston Hanshin 15HP

Giá bán: Liên hệ

Máy nén khí Hanshin Hàn Quốc

Giá bán: Liên hệ

Máy nén khí Sung Shin FORT 20

Giá bán: Liên hệ

Máy nén khí Sung Shin không dầu ZW

Giá bán: Liên hệ

Dầu máy nén khí SHL - SHL Compressor Oil

SHL là tên thường gọi của Shanhwa Lube Oil có nguồn gốc từ Hàn Quốc, là dòng dầu nhờn có hiệu suất cao, được tạo thành từ các nguyên liệu chất lượng cao, hệ thống sản xuất tiên tiến hiện đại, được thiết kế phù hợp với các dòng máy nén khí công nghiệp đảm bảo hoạt động ổn định của máy kể cả trong môi...