Air Lead Audit and Detection Program

Stop wasting air and start lowering energy costs

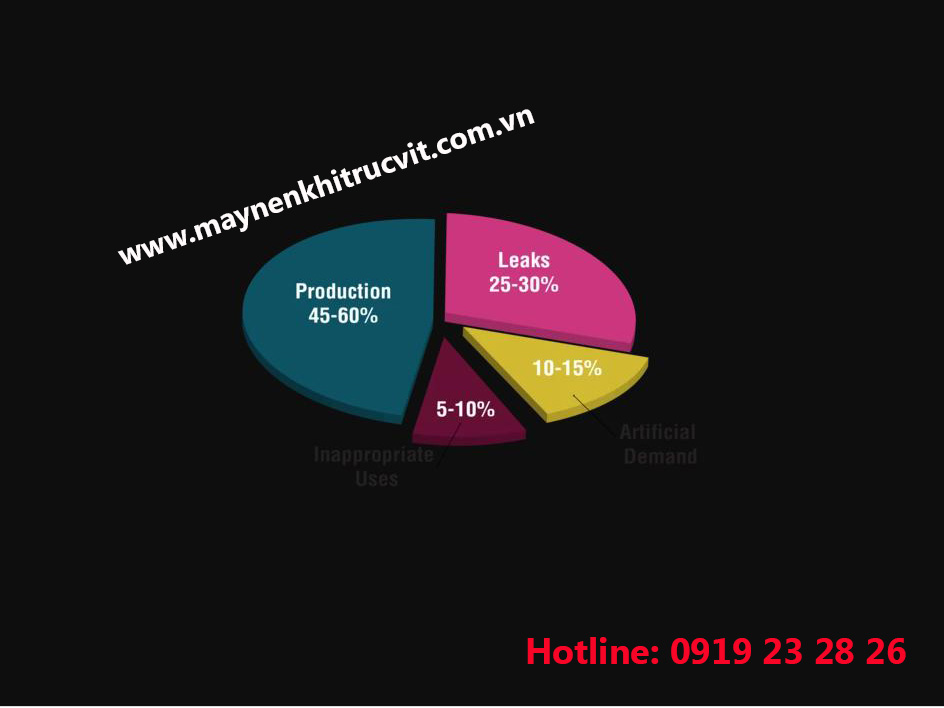

The US Department of Energy estimates 25% of compressed air is lost to leaks - and it's higher in many plants. Kaeser's compressed air leak detection and repair program is a smart solution for facilities ready to stop wasting air and start lowering energy costs

Fixing even a fraction of the leaks provides immediate payback. Plus, reducing compressed air leaks increases service life, frees-up capacity for production surges and growth, and stabilizes system pressure.

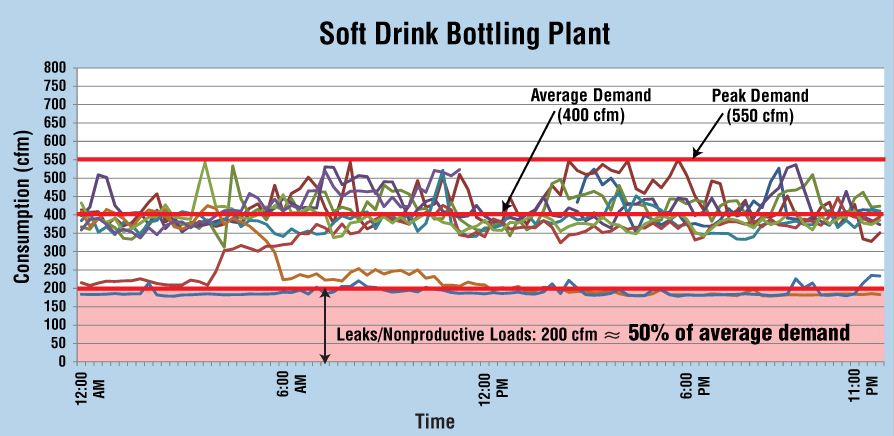

High Cost of Leaks: Example 1

A small soft drink bottler was losing approximately half of the average air consumption to leaks - costing the company over $34,000 annually in electricity.

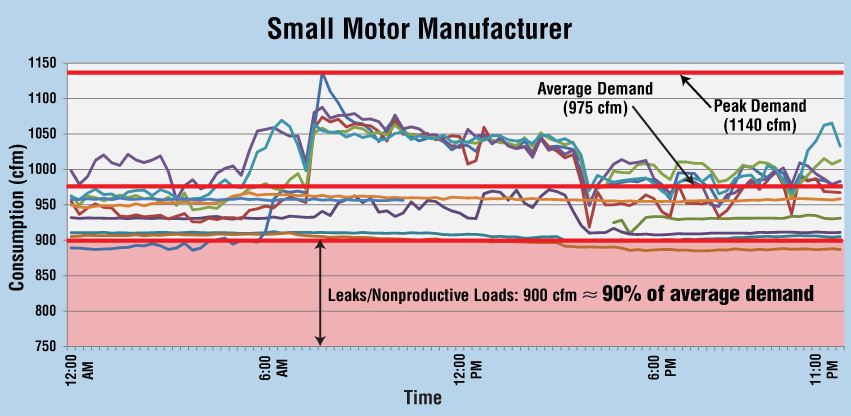

High Cost of Leaks: Example 2

At a small motor manufacturer, over 90% of the plant's average air production is wasted to leaks – representing as much as $70,000 in electricity each year.

Những tin mới hơn

Những tin cũ hơn